|

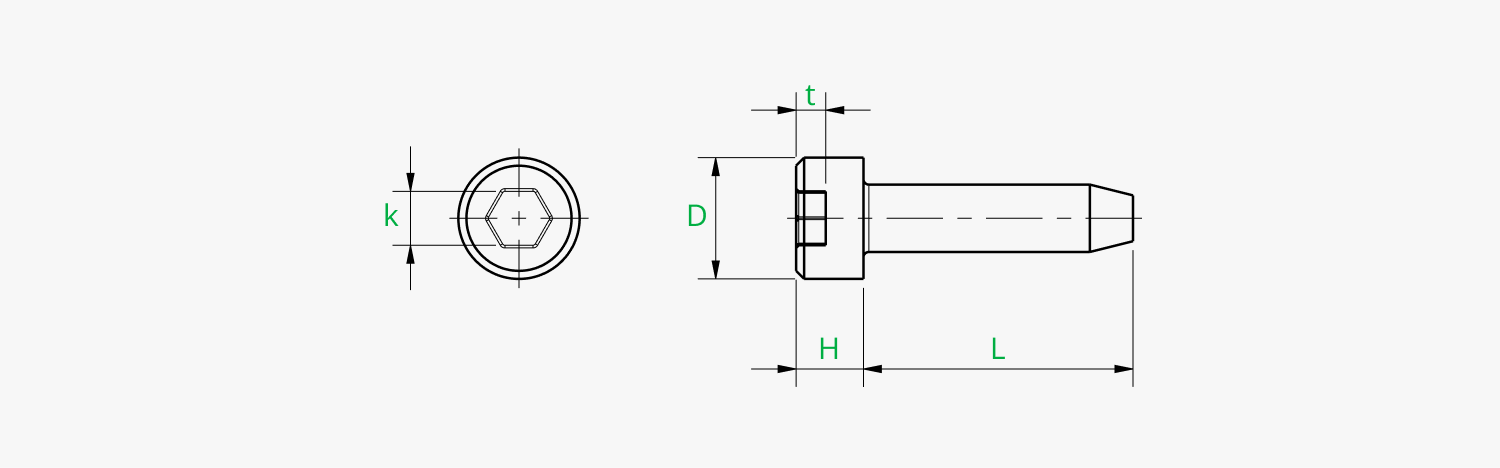

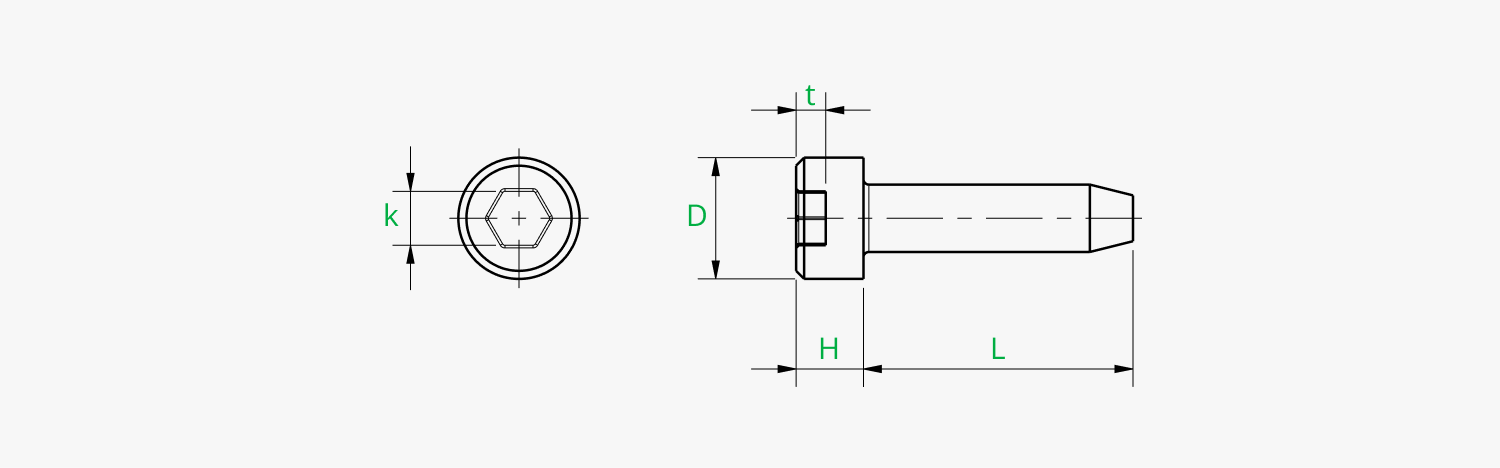

Product ID

|

L (mm)

Bolt Length |

D (mm)

Head Diameter |

H (mm)

Head Thickness |

k (mm)

Hexagon Across Flats |

t (mm)

Groove Depth |

Screwdriver Bit

Size |

| AA199 | 5 | 5.5 | 1.9 | 2 | 1 | H2 |

| AA107 | 6 | 5.5 | 1.9 | 2 | 1 | H2 |

| AA108 | 8 | 5.5 | 1.9 | 2 | 1 | H2 |

| AA200 | 10 | 5.5 | 1.9 | 2 | 1 | H2 |

| AA109 | 12 | 5.5 | 1.9 | 2 | 1 | H2 |

| AA201 | 14 | 5.5 | 1.9 | 2 | 1 | H2 |

| AA110 | 16 | 5.5 | 1.9 | 2 | 1 | H2 |

| AA202 | 18 | 5.5 | 1.9 | 2 | 1 | H2 |

| AA111 | 20 | 5.5 | 1.9 | 2 | 1 | H2 |

| AA112 | 25 | 5.5 | 1.9 | 2 | 1 | H2 |

| AA113 | 30 | 5.5 | 1.9 | 2 | 1 | H2 |

Forgot the screw specs? Just tap the Screw Gauge for sorting help.

For 3D printed parts, which often have gaps between layers and varying hole sizes, we recommend using BT self-tapping screws. These screws provide moderate torque for insertion, prevent loosening, and can be installed and removed multiple times. Using these screws and matching them with the recommended hole size ensures easy and secure connections for your printed parts, eliminating the need for nuts and avoiding issues like screw loosening or hole shrinkage.

We have included the relevant data for the twisting torque and loosening torque experiments of PLA and PETG material specimens, as well as the recommended hole sizes for design. The model files for testing are available for download at the end of the details page. All test holes are printed perpendicularly to the platform. When designing a bolt bottom hole on the side of the part, it is recommended to use a size one size larger than the recommended size for lying flat to prevent interlayer compression cracking.

| Surface Treatment | Black zinc-nickel alloy plating |

| Mounting Hole Shape | Hex socket |

| Screw Type | Complete thread |

| Material | Carbon steel |

| Thread Ridge Type | Metric coarse |

| Color | Black |

Self-Tapping Screws for 3D Printing

Carbon Steel Socket Head Cap Self Tapping Screw (SHCS)

Nominal thread: BT1.6~BT3

Strength grade: 4.8

Type of thread: Metric coarse thread

Full thread series