Bambu ASA Aero is a self-foaming material renowned for its exceptional durability and toughness. Its heat-sensitive foaming allows for controlled model density, resulting in feather-light print models. Additionally, it boasts extraordinary resistance to temperature, water, and UV rays. With these unique properties, it is ideal for printing long-lasting outdoor models and weight-sensitive projects, such as RC planes.

Compared with other foaming filament, ASA Aero is tougher with higher layer strength, making it more resistant to impact, collision, and falling, perfect for high-stress demanding applications.

|

Bambu ASA Aero

|

Bambu PLA Aero | Wood PLA | |

| Toughness (Impact Strength - XY) |

32.0 kJ/m²

|

24.5 kJ/m² | 7.9 kJ/m² |

| Layer Adhesion (Impact Strength - Z, Dry State) |

3.4 kJ/m²

|

2.5 kJ/m² | 1.1 kJ/m² |

| Layer Strength (Bending Strength - Z) |

24 MPa

|

15 MPa | 15 MPa |

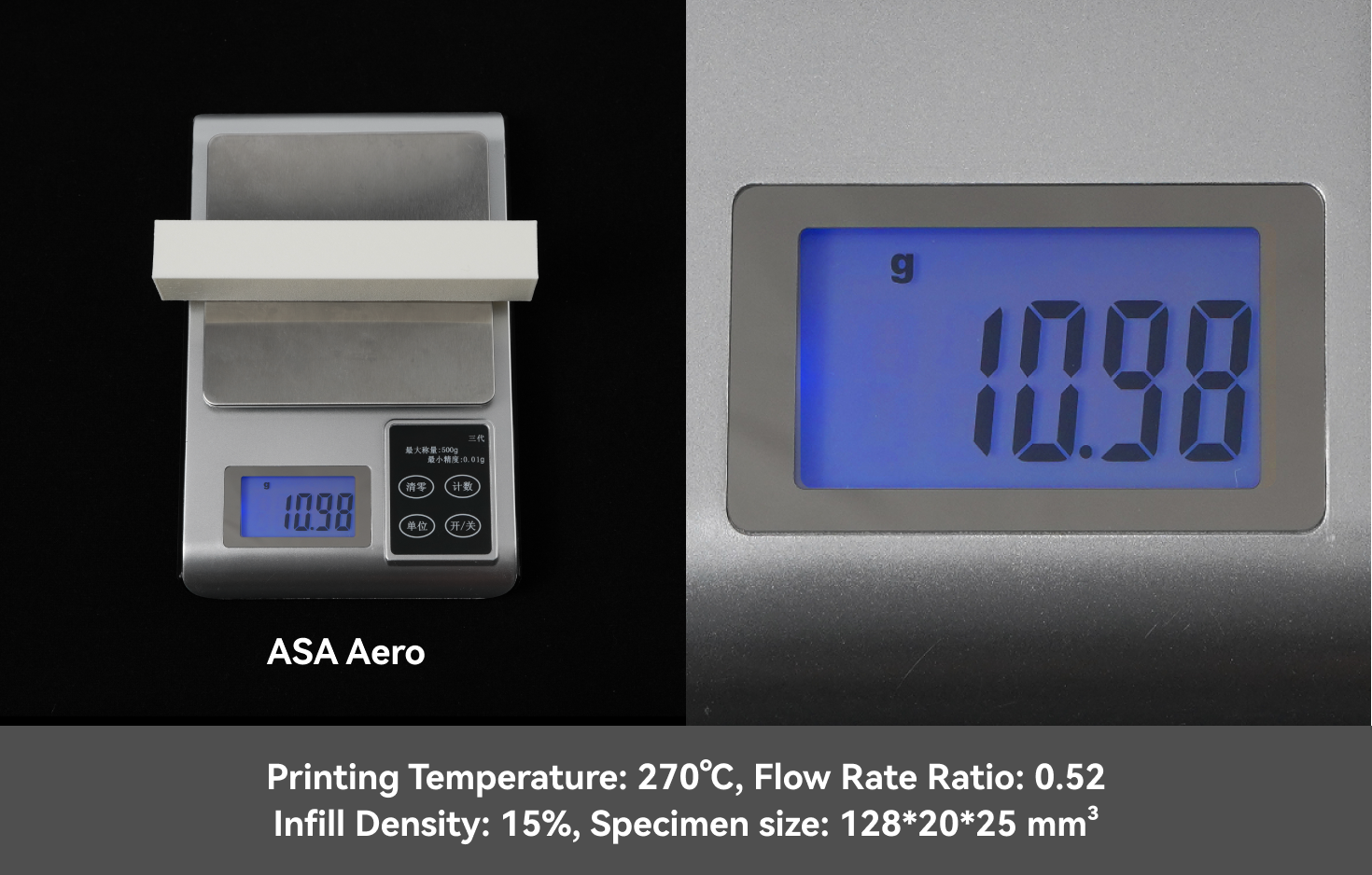

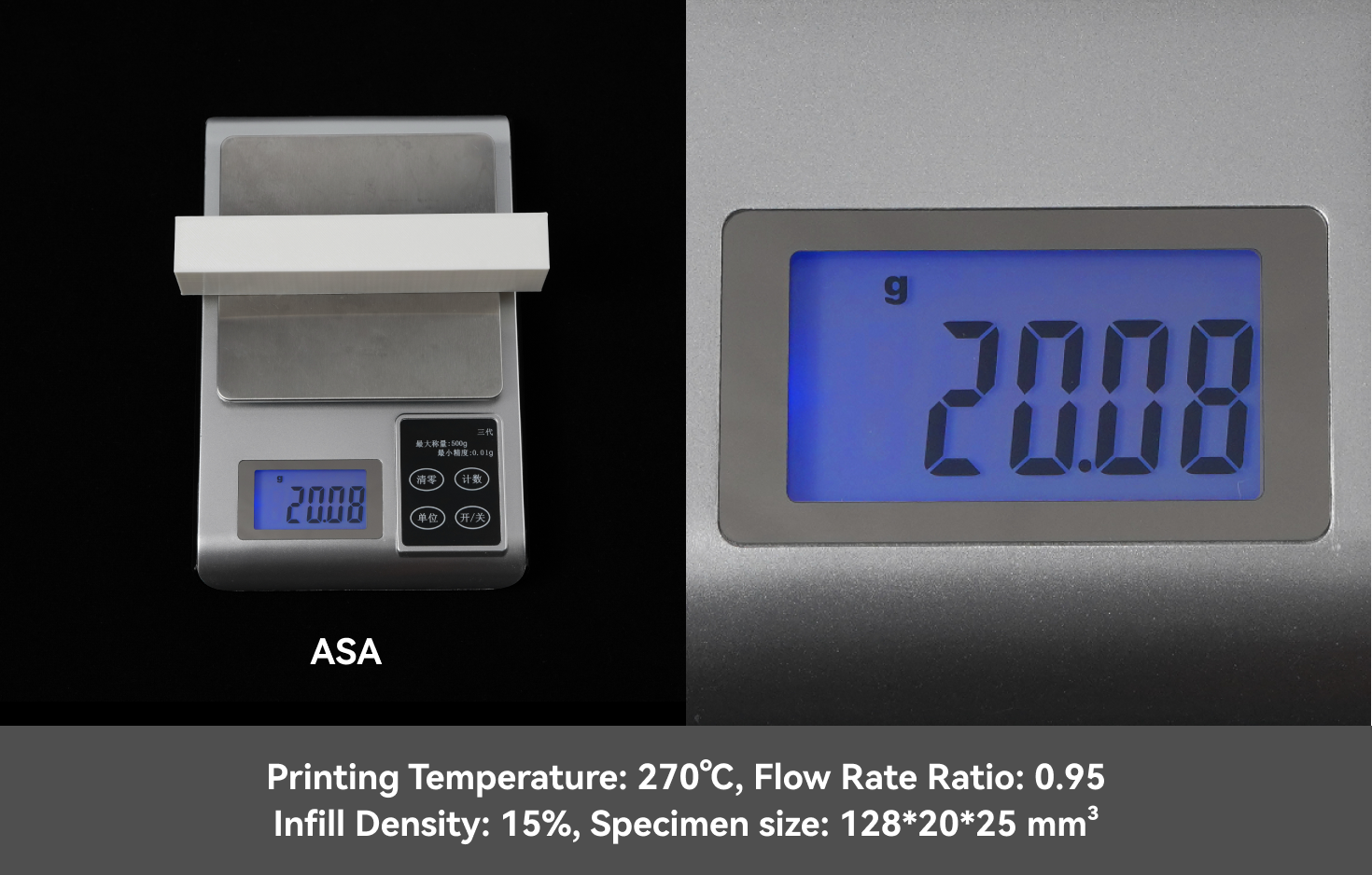

Only 50%-75% the density of regular ASA prints, ASA Aero is as light as feather, designed for weight-sensitive objects, such as RC planes and unmanned aerial vehicles (UAVs). With controllable foaming characteristic, ASA Aero achieves lower density of prints by increasing printing temperature or lowering flow rate.

The average density of prints will vary with changes in parameters such as actual printing temperature, flow rate ratio, printing speed, model size, wall thickness and infill density.

|

Parameter Setting

|

Average Density

|

|

| Printing Temperature | Increases ↗ | Decreases ↘ |

| Printing Speed | Increases ↗ | Stable or Increases ↗ |

| Flow Rate Ratio | Increases ↗ | Increases ↗ |

| Model Size | Increases ↗ | Decreases ↘ |

| Wall Thickness(Wall loops) | Increases ↗ | Increases ↗ |

| Infill Density | Increases ↗ | Increases ↗ |

The relationship between the maximum foaming rate, minimum print density, and printing temperature of ASA Aero.

|

Printing Temperature

|

Minimun Flow Rate Ratio

|

Maximum Volumetric Expansion Ratio

|

Maximum Foaming Rate

|

Minimum Prints Density

|

| 220 °C | ~ 0.93 | ~ 100% | ~ 0% | ~ 0.97 g/cm³ |

| 230 °C | 0.90 | 106% | 6% | 0.92 g/cm³ |

| 240 °C | 0.74 | 128% | 28% | 0.78 g/cm³ |

| 250 °C | 0.60 | 158% | 58% | 0.61 g/cm³ |

| 260 °C | 0.51 | 186% | 86% | 0.52 g/cm³ |

| 270 °C | 0.45 | 211% | 111% | 0.46 g/cm³ |

| 280 °C | 0.44 | 216% | 116% | 0.45 g/cm³ |

Specimen Test: Nozzle Type: 0.4 mm; Printing Speed: 80 mm/s; Model size (L*W*H): 80*10*4 mm³ (the XY direction)

The actual required flow rate ratio and final model density may vary with different models.

Compared with PLA Aero, the overwhelming performance in temperature, water, and UV resistance makes ASA Aero stand out for long-lasting outdoor use and harsh environments.

| Filament Type | Bambu PLA Aero | Bambu PLA Basic |

Bambu ASA Aero

|

Bambu ASA |

| Heat Deflection Temperature / °C (0.45 MPa) | 53 °C | 57 °C |

85 °C

|

100 °C |

Bambu ASA Aero provides an easy-to-color matte surface texture with better dyeing results as compared with regular ASA.

Learn more different filaments comparison on Bambu Filament Guide >>

| Bambu ASA |

Bambu ASA Aero

|

Bambu PLA Aero | |

| Printing Temperature | 240 - 270 °C |

240 - 280 °C

|

210 - 260 °C |

| Printing Speed | < 250 mm/s |

< 150 mm/s

|

< 180 mm/s |

| Flow Rate Ratio | 0.93 - 0.97 |

0.45 - 0.80

|

0.5 - 0.8 |

| Filament Density | 1.05 g/cm³ |

0.99 g/cm³

|

1.21 g/cm³ |

| Foaming Rate | / |

0 - 110%

|

0 - 120% |

| Volumetric Expansion Ratio | 102% |

100% - 210%

|

100% - 220% |

| Prints Density | 1.03 g/cm³ |

0.46 ~ 0.97 g/cm³

|

0.55 - 1.05 g/cm³ |

| Recommended | Not Recommended | |

| Build Plate | Smooth PEI Plate, Textured PEI Plate | Cool Plate SuperTack |

| Hotend | Hotend with Hardened Steel Nozzle 0.4 mm Hotend with Stainless Steel Nozzle 0.4 mm |

Hotend with Hardened Steel Nozzle 0.6 mm / 0.8 mm Hotend with Stainless Steel Nozzle 0.2 mm |

| Glue | Bambu Liquid Glue Glue Stick |

/ |

| Color | Hex Code | Display | |

| White | #F5F1DD | ||

All printing parameters are embedded in RFID, which can be read through our AMS (Automatic Material System).

Load and print! No more tedious setting steps.

| Recommended Printing Settings | |

| Drying Settings (Blast Drying Oven) | 80 °C, 8 h |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 240 - 280 °C |

| Bed Temperature (with Glue) | 80 - 90 °C |

| Printing Speed | < 150 mm/s |

| Physical Properties | |

| Density | 0.99 g/cm³ |

| Vicat Softening Temperature | 80 °C |

| Heat Deflection Temperature | 85 °C |

| Melting Temperature | 204 °C |

| Melt Index | 1.56 ± 0.5 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 32 ± 4 MPa |

| Breaking Elongation Rate | 5.1% ± 1.6% |

| Bending Modulus | 1510 ± 120 MPa |

| Bending Strength | 58 ± 6 MPa |

| Impact Strength | 32.0 ± 2.5 kJ/m² |

• Foaming ASA materials (ASA Aero) have high requirements for material drying and parameter settings. Please carefully read ASA Aero Printing Guide before starting the printing process.

• Drying conditions: 80℃ for 8 hrs. ASA Aero is highly sensitive to humidity. To achieve optimal printing performance, it is recommeded further drying before use and after storage. For more details please refer to: Filament Drying Recommendations on WIKI.

• To minimize warping, avoid printing large-sized high infill density models. Use enclosed printers and ensure the build plate is properly applied with glue for better print adhesion before printing. Set lower printing speed and higher heatbed temperature. For more details please refer to: Common print quality problems and solutions on WIKI.

• Pungent and unpleasant odors may be released during printing. Make sure your printer is placed in a well-ventilated area and use enclosed printers.

Filament with Spool*1 & Desiccant*1

Package*1